High level of economy

You want to reduce the costs of water, energy and detergents? Our machine innovations help you to achieve significant savings in your operating costs. We combine high efficiency with premium quality: Compared to conventional machines, our warewashing solutions offer a multitude of new features which increase the performance, efficiency and capacity of your dishwasher, resulting in a major reduction of your operating costs.

Eco programmes

High performance at low consumption

Fast and still economic: Low water consumption and short programmes are important factors to reduce costs and save time. The intelligent HOBART PREMAX models therefore use steam, which gives you unbeatable benefits:

- Optimal results are achieved with up to 1.0 l fresh water in rinsing

- This reduces the water and detergent consumption by up to 60 %

HIGHER WASH TEMPERATURES REDUCE PROGRAMME DURATION

- With the PREMAX FP, the shortest programme takes only 80 seconds. With the PREMAX hood-type dishwashers it is even as short as 55 seconds.

SENSO-ACTIVE resource management

The responsible water consumption

Rinsing intelligence of the special kind: The water quality is monitored continuously, resulting in a continuous automatic adjustment of the water consumption. A low level of soil consumes little water; for a higher level of soil, the machine uses more water.

OPERATING COSTS ARE REDUCED

Merely the innovative use of resources reduces the operating costs by up to 20 %.

- Reliable wash results with a high level of soil

- The dishwasher corrects operating mistakes

- Complete pump out and refill is not necessary anymore

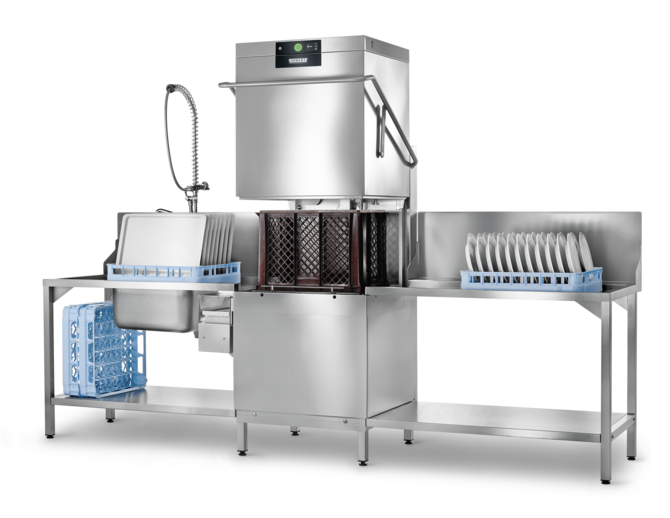

Double capacity

The TLW provides twice the capacity of a conventional hood-type dishwasher, thanks to an additional wash chamber - but with the same space requirement.

Space saving wash organisation

For heavily soiled wash ware, theTLW has a special utensil wash programme. Due to the extended washing time, the pre-soaking effect is already integrated into the washing process, so that the wash ware no longer need to be pre-soaked. This

saves valuable space in the kitchen organisation.

Intelligent energy management

To reduce the total connected load of hood-type dishwashers, commercial machines reduce the heating power in the hot water tank. However, it takes twice as much time to heat up.

WE HAVE THE SOLUTION

Thanks to the intelligent energy management of HOBART hood-type dishwashers, the maximum boiler capacity is always available for filling. This reduces the filling time.

To provide energy for wash pump and tank heater, the booster loading can be reduced to the necessary medium during the washing operation.

Thanks to the intelligent use of the available energy, short heating times at a reduced total connected load of the machine are ensured.

Higher capacity and flexibility

Increase your capacity with our lateral guide rails for GN plates and butchery boxes. Compared with conventional models, you wash significantly more in each cleaning process.

AT ONE GLANCE

- The PREMAX UP triples the capacity from 2 to 6 GN plates.

- The PREMAX UPT doubles the capacity from 4 to 8 GN plates.

2IN1 double rack system

for double capacity

Twice the washing volume - half the costs: Since two racks can be washed simultaneously, the double rack system significantly increases the capacity of your undercounter dishwasher. The top rack can be placed on an extendable rack carrier.

THIS MEANS FOR YOU: Thanks to the optimum use of the dishwasher capacity, it is possible to reduce the consumption of water, energy and chemicals by 50 % compared to conventional usage.

KEY DATA

- The top rack accommodates plates with a maximum diameter of 250 mm

- The bottom rack has room for cups, glasses and small bowls of a max. height of 110 mm

Exhaust energy storage

the clever way of saving energy

Energy saving - easy and convenient: The standard exhaust energy storage significantly reduces the energy consumption of a hood-type dishwasher. Due to the completely closed hood, the hot waste steam remains in the system and is not dissipated to the room. The stored thermal energy can thus be reused.

YOUR RESULT: You can thus save up to 3,120 kWh per year. At the same time, the room climate in the scullery is improved noticeably.

Exhaust heat recovery

Using the available energy of the 60 °C waste steam, the optional exhaust heat recovery heats the incoming fresh water.

EFFICIENT UTILISATION: Humidity and energy do not escape uncontrollably into the room, but are returned efficiently to the dishwasher through a heat exchanger.

- Saves up to 5,000 kWh per year

- Reduces the room temperature

- Improves the room climate

Drain heat recovery

Clever use of the waste water: The energy of the 60 °C hot waste water is used to heat fresh water.

THIS IS HOW IT WORKS: The optional drain heat recovery leads the hot waste water along the fresh water that is flowing in. This heats the fresh water up to 45 °C when it enters the boiler where it is heated up to the necessary rinse temperature.

YOUR BENEFITS

- Saves up to 6,350 kWh per year

- Pays off in the 2nd year already

Heat and noise insulated hood

Keep the heat in the machine. Also during operation, the heat is retained in the system. The rinse water is not cooled down at the hood walls with a 15-mm insulation. This increases heat utilisation and saves energy.